As metal cutting, marking and engraving becomes more popular in manufacturing, the competition among North American metal fabricators continues to grow. Metal fabricators are looking for any competitive advantage they can find in order to separate themselves from each other when trying to earn a clients business. These clients are demanding faster throughput speeds, higher quality results and lower prices.

The Fiber Advantage

In 2008, metal fabricators purchased record amounts of fiber laser systems as opposed to the outdated Co2 laser systems, Nd:Yag systems, saws, and plasma cutters to gain these advantages. Fiber laser systems have proven themselves to be the future in metal fabrication and have shown an immediate impact on metal fabricators bottom lines and here is why:

1) Using fiber laser technology has many advantages for metal fabricators, but first and foremost – fiber lasers cut what Co2 lasers cannot, specifically brass, copper and other highly reflective materials. Imagine what that alone could do for business?

2) The fact that fiber laser systems are the most reliable and controllable type of laser to date is another plus.

3) The positive aspects of fiber lasers do not stop there - due to the makeup of the laser itself, the quality and precision of these systems is perfect when dealing with a metal substrate compared to alternative methods.

4) The cost savings of the overall process is what makes most metal fabricators convert to fiber laser systems.

There is a cost comparison calculator which can be found at http://www.laserphotonics.com/ that is a great tool to determine the savings between these two types of laser systems.

Quality

When comparing the quality of the end product, fiber laser systems are rated better in terms of performance with metals than other methods. Due to the wavelength, delivery method and pulsing capabilities fiber laser marking and engraving systems are reaching new levels in clarity and cycle time. Other laser systems, such as Co2 systems, create laser bounce back when marking or engraving highly reflective metal surfaces. This bounce back causes portions of the laser beam to bounce back towards the lens causing damage and requiring lens replacement. Fiber lasers, because of the wavelength, do not have this problem when marking or engraving metals. The laser beam has more absorption there for creating a faster, more accurate mark with less power and longer lens life.

Laser cutting has been a major investment for metal fabricators over the years and one of the main reasons they have switched to laser cutting systems is the quality of the cut over other traditional methods. Fiber laser technology has taken that quality and enhanced it with a smaller beam width, allowing for less waste and more production. As with marking, the same capabilities from fiber lasers with cutting metals are true. Cutting highly reflective metals with a high power fiber laser cutting system is found to create a better cut edge because of the wavelength absorption. Most other forms of cutting requires a second step in the process to complete a finished piece of cut metal, with laser cutting this is not the case and with fiber laser cutting the higher edge quality allows for higher throughput and acceptance by customers.

Cost Savings

Many metal fabricators today have a pulse on the economic woes facing the manufacturing industry. These businesses must find more economic ways to stay competitive while maintaining or increasing the quality their customers are accustomed. Laser cutting and marking systems have always been the best way to increase the quality of processed parts, but in the past have always been thought of as a much larger investment than the return. In keeping with that antiquated thinking module, conventional methods, such as saws, and plasma cutters, have been the less expensive initial investment for metal fabricators. However, after thoroughly analyzing those costs, the actual physical cost of conventional equipment verses a fiber laser system is equal. The real price difference is in the installation costs. They are significantly lower for fiber laser systems, to the tune of $20,000 to $85,000, once the costs of the lines, slab, etc. are considered and calculated. So in actuality, the installed cost of a fiber laser system is 10-20% lower than a conventional system.

A Fiber System will Reduce Costs - Consider the Savings

· Time Savings – Fiber lasers increase throughput speeds! Using conventional methods like saws and plasma cutters it takes many hours to complete jobs. Additionally, because the quality of the cuts is lower, they require a second or even a third set of machines for post processes, each adding more time to finish the job.

· Repair Savings - Fiber laser systems are virtually maintenance free! Because of this, the need for maintenance plans from the manufacturer or additional maintenance employees is eliminated. Co2 systems are prone to maintenance issues with lens failures and alignment as well as additional routine maintenance needed for the laser.

· Down Time Reduction - Fiber lasers are reliable! The Co2 lasers window mean time between failure is 20,000 hours, where the fiber laser is between 50,000 and 100,000 hours.

· Consumable Gas Savings - Fiber laser systems do not require consumable gases to create the laser beam! Co2 lasers require a substantial amount of consumable gases to produce the laser beam. These costs add up to tens of thousands of dollars a year.

· Energy Savings - Fiber lasers are energy efficient! The fiber laser Fiber lasers are twenty times more energy efficient than Co2 systems resulting in not only tens of thousands of dollars a year in savings but are helping companies in their efforts to become more environmentally friendly.

· Set up Savings – Fiber lasers cost less to install! When purchasing a Co2 laser system most shops do not take into account additional set up fees which can run anywhere from $20,000 to $85,000. Co2 systems, due to their size and make up usually need a foundation slab, gas lines, specific electrical hook-ups, etc.

What Does This All Mean?

It is no secret that metal fabricators across the nation have done their research on fiber laser technology and these savings. The quick moving fabricators who have implemented these systems are using it to their advantage in three main ways. Firstly, since the cost of production is significantly lower than other methods, owners are charging the same rates as the past and pocketing the difference. In some cases, due to the quality of the results they may even be able to charge more which drastically increases profits. Secondly, since there is now no post processing steps to the metals it is speeding up their throughput. This means they can beat out their competitors by offering quicker delivery times and again saves money by not having to pay to run the machine or the payroll it involves. This faster throughput also frees up the machine enabling the shop to book more jobs in the same amount of time. Finally, many fabricators are passing this savings onto their clients resulting in significantly lower prices. This allows them to gain more local market share putting a lot of pressure on their competition, if not eliminating them completely.

Technology moves quickly in every industry and market. We live in a world where manufacturing is getting faster, easier and with a higher quality result. The metal fabrication industry is no different and in order to keep up with the completion these shops must move forward quickly. Fiber laser systems are the next step in reducing costs while increasing production and profits. Looking towards the future it is safe to say that in the next decade these systems will fill the majority of these shop floors.

.jpg)

.jpg)

.jpg)

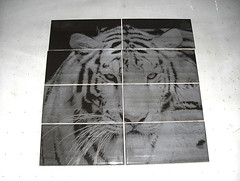

Laser Marking

Laser Marking

Laser Marking

Laser Marking

.jpg)

Clr09_400px.jpg)